FILTERS

| Image | Product | Category | Availability | Price (Includes GST) |

|---|---|---|---|---|

|

ITEM NAME ANSELL ALPHATEC 4000-GR COVERALL HOOD 111, LARGE (PACKING:10PCS/CSE) INVENTORY CODE AEU4000SL GROUP CODE OVI4000 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT COVERALL (DISPOSABLE) |

IN STOCK SG 790 PIECE SIZE COLOR |

SGD $79.38EACHPIECE |

|

ITEM NAME ANSELL ALPHATEC 2000-WH STD COVERALL HOOD 111, X LARGE (PACKING : 40PCS/CSE) INVENTORY CODE AEU2000SXL GROUP CODE OVI2000 |

BRAND ANSELL APPAREL DISPOSABLE COVERALL- (GENERAL) |

IN STOCK SG 4,170 PIECE SIZE COLOR |

SGD $9.57EACHPIECE |

|

ITEM NAME ANSELL BLUE VINYL SLEEVES 18", LIGHTWEIGHT 8MIL (144PR/CSE) INVENTORY CODE AEU59001 GROUP CODE AEU59001 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT SLEEVES |

IN STOCK SG 323 PAIR SIZE COLOR |

SGD $4.81EACHPAIR |

|

ITEM NAME ANSELL EDMONT YELLOW NEOPRENE 18" SLEEVES ELASTIC BOTH ENDS (192PCS/8DOZ-PR/CSE) INVENTORY CODE AEU59050 GROUP CODE AEU59050 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT SLEEVES |

IN STOCK SG 264 PAIR SIZE COLOR |

SGD $21.88EACHPAIR |

|

ITEM NAME ANSELL EDMONT BLUE COAT APRON 8MIL, SIZE L INVENTORY CODE AEU56910L GROUP CODE AEU56910 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT APRON |

IN STOCK SG 242 PIECE SIZE COLOR |

SGD $65.19EACHPIECE |

|

ITEM NAME ANSELL ALPHATEC 58-535B, NITRILE, GRIP GLOVES 13.4", 13MIL, SZ 8 (6PAIRS/12BAGS/CSE) INVENTORY CODE AEU58535BS8 GROUP CODE AEU58535B |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

IN STOCK SG 396 PAIR SIZE COLOR |

SGD $21.58EACHPAIR |

|

ITEM NAME ANSELL ALPHATEC 3000-YE COVERALL HOOD 111, LARGE (PACKING:20PCS/CSE) INVENTORY CODE AEU3000SL GROUP CODE OVI3000 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT COVERALL (DISPOSABLE) |

IN STOCK SG 109 PIECE SIZE COLOR |

SGD $36.57EACHPIECE |

|

ITEM NAME ANSELL EDMONT YELLOW HYCAR APRON, 18OZ HEAVYWEIGHT INVENTORY CODE AEU56510 GROUP CODE AEU56510 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT APRON |

IN STOCK SG 58 PIECE SIZE COLOR |

SGD $54.69EACHPIECE |

|

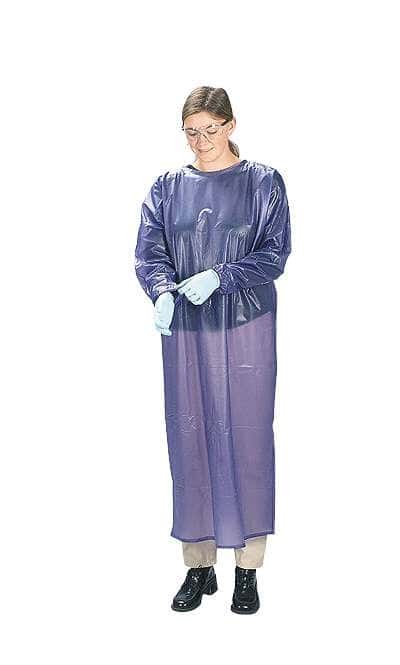

ITEM NAME ANSELL ALPHATEC 4000-GR MODEL 215 APRON WITH SLEEVES, X LARGE INVENTORY CODE AEU4000-215SXL GROUP CODE OVI4000-215 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT COVERALL (DISPOSABLE) |

IN STOCK SG 5 PIECE SIZE COLOR |

SGD $62.94EACHPIECE |

|

ITEM NAME ANSELL EDMONT NEOTOP, UNSUPPORTED NEOPRENE/ LATEX FLOCKLINED, SIZE LARGE INVENTORY CODE AEU29500SL GROUP CODE AEU29500 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL ALPHATEC KNIT LINED NITRILE CHEMICAL RESISTANT GLOVES: 13 MIL, 14" LENGTH, SIZE 10 INVENTORY CODE AEU58535S10 GROUP CODE AEU58535 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL ALPHATEC® 58-530B KNIT LINED NITRILE GLOVES 12",13MIL , SZ 10 INVENTORY CODE AEU58530BS10 GROUP CODE AEU58530BS10 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL APS SPLASH SUIT FIREMAN SABF BOOTS, SIZE 11.5/47 INVENTORY CODE AEUK72204470 GROUP CODE AEUK72204470 |

BRAND ANSELL FOOTWEAR FIREMAN BOOTS |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL EDMONT HEAVY DUTY GREEN PVC APRON 20 MIL 35" X 50" (12DOZ/CSE) INVENTORY CODE AEU56100 GROUP CODE AEU56100 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT APRON |

OUT OF STOCK SG 0 PIECE SIZE COLOR |

|

|

ITEM NAME ANSELL EDMONT SOLVEX UNSUPPORTED NITRILE CHEMICAL RESISTANT GLOVES 15MIL,13", STRAIGHT CUFF S10 (144PR/CASE) INVENTORY CODE AEU37155S10 GROUP CODE AEU37155 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL EDMONT IMPROVED PVA 14" CHEMICAL RESISTANT GLOVES S10 (1DOZ/CASE) INVENTORY CODE AEU15554 GROUP CODE AEU15554 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL ALPHATEC 4000-GR MODEL 301 TROUSERS, STITCHED & TAPE SEAMS, ELASTICATED WAIST & ACKLES, LARGE (25 PCS/CASE) INVENTORY CODE AEU4000-301L GROUP CODE OVI4000-301 |

BRAND ANSELL APPAREL CHEMICAL RESISTANT COVERALL (DISPOSABLE) |

OUT OF STOCK SG 0 PIECE SIZE COLOR |

|

|

ITEM NAME ANSELL ALPHATEC 58-530 KNIT LINED NITRILE CHEMICAL RESISTANT GLOVES 12",13MIL , SIZE 7 INVENTORY CODE AEU58530S7 GROUP CODE AEU58530 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL EDMONT NEOPRENE UNSUPPORTED CHEMICAL RESISTANT GLOVES 17MIL, 12", STRAIGHT CUFF S7 INVENTORY CODE AEU29845S7 GROUP CODE AEU29845 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

|

|

ITEM NAME ANSELL ALPHATEC 38-514 BUTYL POLYMER CHEMICAL RESISTANT GLOVES: 14 MIL, 14" LENGTH, SIZE 10 INVENTORY CODE AEU38514S10 GROUP CODE AEU38514 |

BRAND ANSELL HAND & ARM CHEMICAL RESISTANT GLOVES |

OUT OF STOCK SG 0 PAIR SIZE COLOR |

Showing 20 of 47 records.